An architect from Turin, in the early 1990s he decided to join his two brothers, the owners of ReeR. The company, which had recently been acquired, began to grow and needed trusted people to lend a hand. Maurizio Scaravelli did not back down and, with twenty years’ experience as a freelancer, began to take charge of purchasing management, a very important and delicate area not only for the company’s economic balance but also for production.

What is your daily work routine like?

Very varied. Also because in addition to purchasing I also deal with the management of works on buildings and projects involving buildings when necessary. Apart from the latter, on a typical day I deal with suppliers and deal with the various critical issues that may arise. I try to ensure that nothing is missing in production, so that the lines never have to stop. Our computer system ensures that there is a constant supply of components.

Then there is the business of evaluating suppliers, looking for other possible companies, evaluating prices and more. Let’s say that we keep an eye on the present but also on medium- and long-term dynamics. We have to respond to complex situations where there are many variables at play. Thanks to the constant dialogue with our sales department, we try to anticipate the evolution of the market and demand so that we are never caught unprepared and are always ready to respond to customers’ future needs.

How is your work team structured?

I have the coordination of two areas, on which two work teams with a total of eight people are engaged. The first area is the one we mentioned a little earlier and which I would define as production logistics: it is the one that deals with ensuring the adequate supply of necessary components at all times. The other area is more properly related to purchasing: once we know what we need and when we need it, we proceed to contact suppliers, negotiate prices, place orders and make sure that the supplies arrive on time and under the best possible conditions.

What do you buy at ReeR?

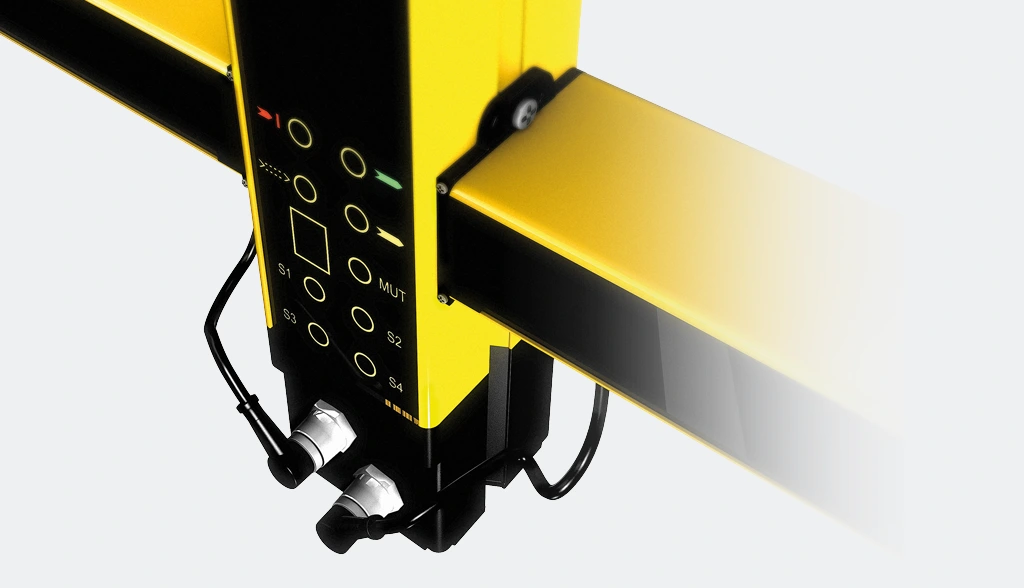

The manufacture of our devices requires components from different product categories. Optoelectronic barriers, for example, require aluminium for the frame, plastic parts, lenses, electronic circuits, chips, connectors, etc. We therefore have to deal with suppliers from various sectors, because our products are complex and, moreover, require expertise in various technical fields for their manufacture: mechanics, physics, optics…

How are suppliers selected?

We look for them through various sources: the Internet, trade fairs, acquaintances, indications given by our other suppliers. Once we have identified companies of interest, an initial selection is made on the basis of evaluation questionnaires and, later, with visits to their factories: in this way we can understand whether what is stated on paper actually corresponds to the production capacity and quality we need. Depending on the type of component we are looking for, we also assess the geographic factor for greater convenience and shorter delivery times. In some cases, these are companies located just a few kilometres from our Turin headquarters; other suppliers are instead located in countries far away, where production is perhaps cheaper or for the simple fact that closer to us there are no companies capable of producing what we need.

When evaluating the supplier, are the working conditions of employees and compliance with local labour regulations taken into account?

Certainly yes. In our evaluation questionnaire, with which we initially screen companies that are candidates to become our partners, there are questions on these aspects. We then visit the factories to ensure that the safety and welfare of the workers in the factory is respected. Our suppliers, at least those of customised parts, are generally not large companies. This makes it easier to realise the quality of the working environment in the company.

Are there also assessments on the ecological front when choosing suppliers?

Yes, and they are carried out by the very people at ReeR who deal with these issues and who always participate in our visits to supplier companies. He is therefore in a position to make his own assessments in this respect.

Over the years, has the economic competitiveness of certain geographical areas, such as Asia, remained as it is or has there been a kind of levelling off with the West?

Speaking of China, we can say that there is almost always a competitiveness. But, even in this country, you now find the same component in every price segment. If I pay 10 euros for a component based on a design in Italy, I can find it in China for 3 or 10 euros, depending on the quality and level of expertise of the manufacturer. There are companies that are able to make products with very high technology, as well as manufacturers that instead make poor quality components that you absolutely cannot take into consideration. You have to be very careful and very prepared.

In the case of a failed supply, is the relationship with the supplier called into question?

At ReeR we have a quality system, based on our Iso 9000 certification, whereby each supplier is monitored and given (and constantly updated) scores with reference not only to the quality of the product but also of the service: i.e. compliance with delivery times, number of pieces delivered, etc. When the score falls below certain thresholds, the supplier is put under observation and corrective solutions are proposed at the same time. If these are implemented correctly and on time, if the required conditions are met, the relationship continues. If not, the supply relationship may even be terminated, no doubt about it. It is all part of our quality system.

How do we cope with times of component shortages?

We have a number of preventive measures. First of all, a good level of stock, which makes it possible to cope at least with the early stages of a period of component shortage, let’s say the first two months.

We then pay a lot of attention to having multiple sources of component supply, particularly for electronic components, which are more prone to times of scarcity. It must be said that we can only buy components from manufacturers that are approved by our technical department. It is therefore good to have several approved manufacturers, because it means having more freedom of movement in the purchasing phase and therefore having a greater probability of obtaining the component, avoiding production stoppages. There is therefore a kind of redundancy of companies you can turn to. Sometimes, unfortunately, there are components produced by only one company. Here, in these cases we have to be careful to always maintain high stocks, but also to make arrangements for continuous and scheduled supplies during the course of the year, so that there are no problems. As a last resort, should problems arise even in these cases, we can look for the missing component on the electronic broker market as a last resort. Here you not only have prices that can be double up to 20 times higher than those implemented by the manufacturer or distributor. But there can also be issues with the quality of the component and compliance with the stated specifications. When we are forced to use these sources, we exponentially increase quality controls to ensure that we do not have problems later in production.

Do ReeR’s foreign subsidiaries and their distributors play a role in component procurement?

Yes, in particular in buying on the brokers’ market when components are scarce. When we resorted to this channel, the support of our subsidiaries and distributors in China was crucial, because the brokers are mostly located in the Far East.

Let’s talk, in closing, about prices: how are they negotiated? And does the human component play a role in this process?

Price setting and bargaining is a very important activity in our work, as you can easily guess. Bargaining margins depend on several factors, including quantity, the type of product, the supplier, and also on the human relationship, friendship, knowledge… not least how long you have been a customer. There are so many variables at play. But I have to say that our purchasing team often manages to get cheaper prices than some of our competitors. And this is further proof of their prowess.

Italiano

Italiano Deutsch

Deutsch Español

Español Português

Português 简体中文

简体中文 한국어

한국어