From theory to practice: the Meccanotecnica case

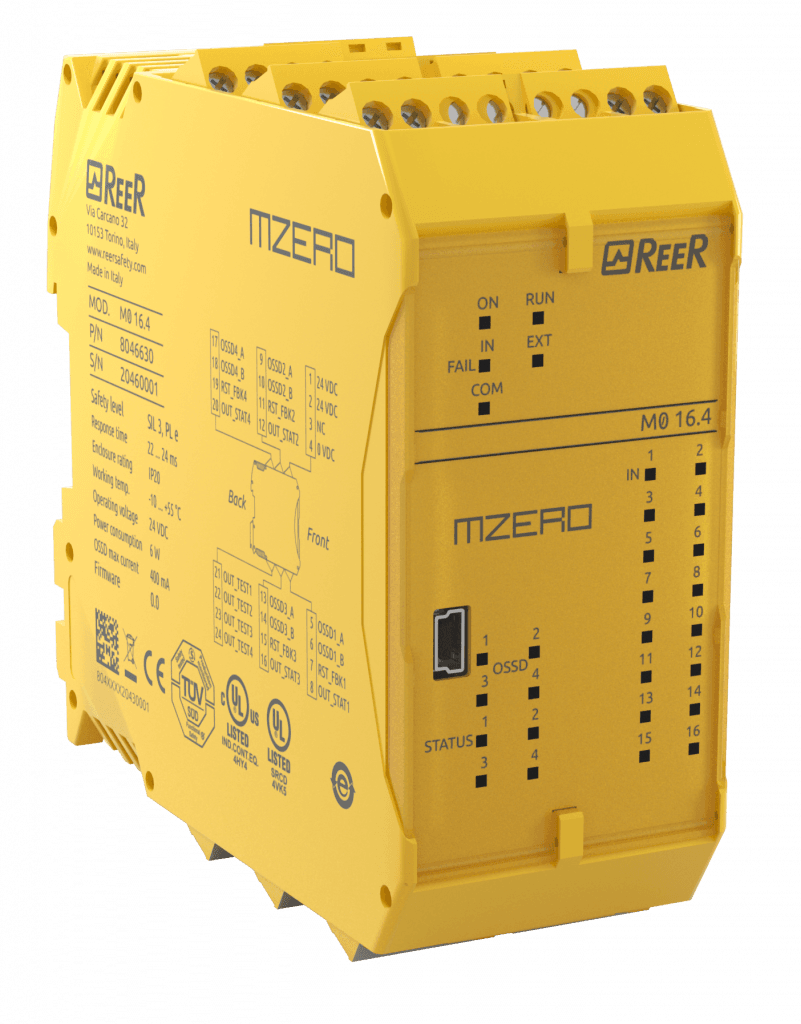

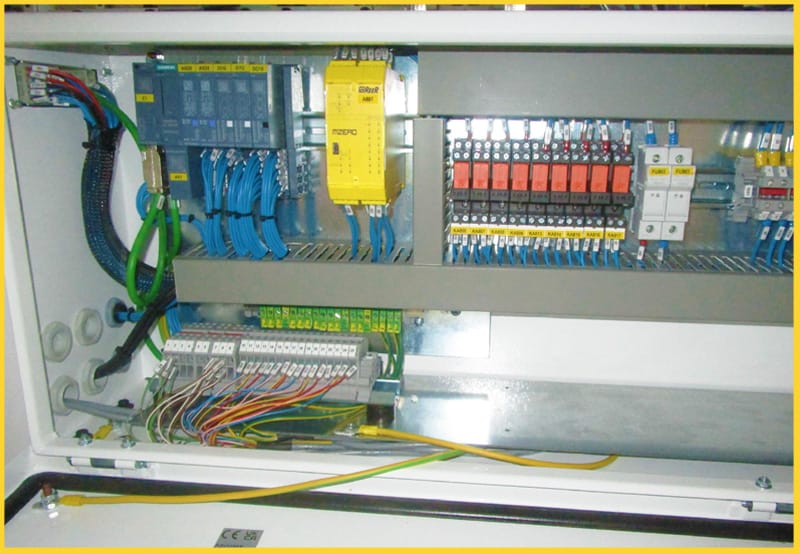

Meccanotecnica, a company based in Torre de’ Roveri (BG), specializes in the production of groups and lines of automatic thread stitchers and industrial bookbinding machines from offset and digital printing. They have chosen MOSAIC MZERO controllers to easily and effectively manage the safety devices installed along their production line.

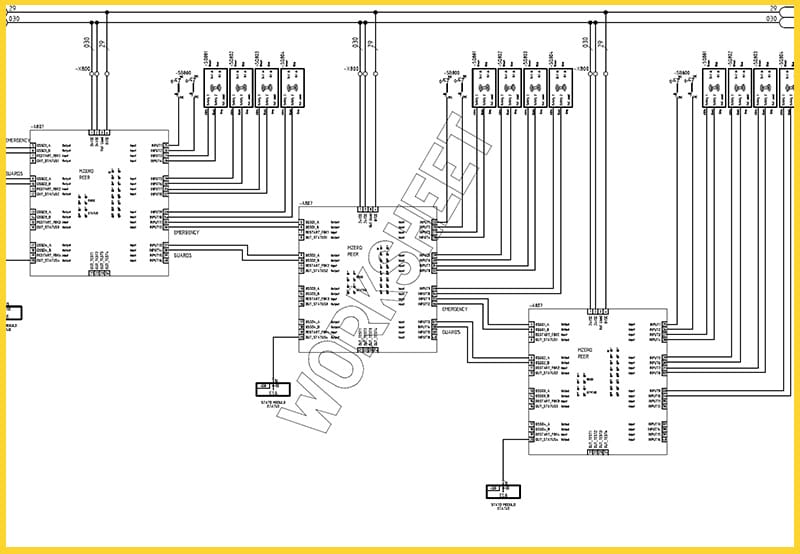

Specifically, the MZERO controller is used on the Multiplex, an automatic book collecting and stitching line. The line consists of MX4 picker modules connected to three stitching units (asterPRO, aster-PRO/52 or asterTOP). The system can be configured with up to 8 modules and used by one or two operators.

Each module of the Multiplex picker is equipped with a MZERO controller that controls 4 RFID sensors attached to the movable guards plus an emergency button and communicates through the module’s local PLC via a coded digital output of the MZERO itself.

The different MZEROs are connected to each other and with individual devices, fewer wiring and power supply cables needed manage to ensure safety control along the entire line.

Configuration and use:

- Each module of the Multiplex harvester is equipped with a MZERO controller.

- The system can be configured up to 8 modules.

- For each module, 4 RFIDs are connected for guards and an emergency button.

Communication and diagnostics:

- Diagnostics between MZERO and the module’s local PLC is via a coded digital output of the MZERO.

- This allows the safety status of the module to be monitored accurately and effectively.

Main function:

- The MZERO manages machinery safety by monitoring access to guards and activation of emergency buttons.

- It ensures compliance with safety regulations, reducing operational risks.